Custom Street Light Pole & Lamp Post with Single Arm

Technical Data

|

Product Name |

Custom Street Light Pole & Lamp Post with Single Arm |

||||||

|

Material |

Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 |

||||||

|

Height |

5M |

6M |

7M |

8M |

9M |

10M |

12M |

|

Dimensions(d/D) |

60mm/150mm |

70mm/150mm |

70mm/170mm |

80mm/180mm |

80mm/190mm |

85mm/200mm |

90mm/210mm |

|

Thickness |

3.0mm |

3.0mm |

3.0mm |

3.5mm |

3.75mm |

4.0mm |

4.5mm |

|

Flange |

260mm*14mm |

280mm*16mm |

300mm*16mm |

320mm*18mm |

350mm*18mm |

400mm*20mm |

450mm*20mm |

|

Tolerance of dimension |

±2/% |

||||||

|

Minimum yield strength |

285Mpa |

||||||

|

Max ultimate tensile strength |

415Mpa |

||||||

|

Anti-corrosion performance |

Class II |

||||||

|

Against earthquake grade |

10 |

||||||

|

Color |

Customized |

||||||

|

Surface treatment |

Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II |

||||||

|

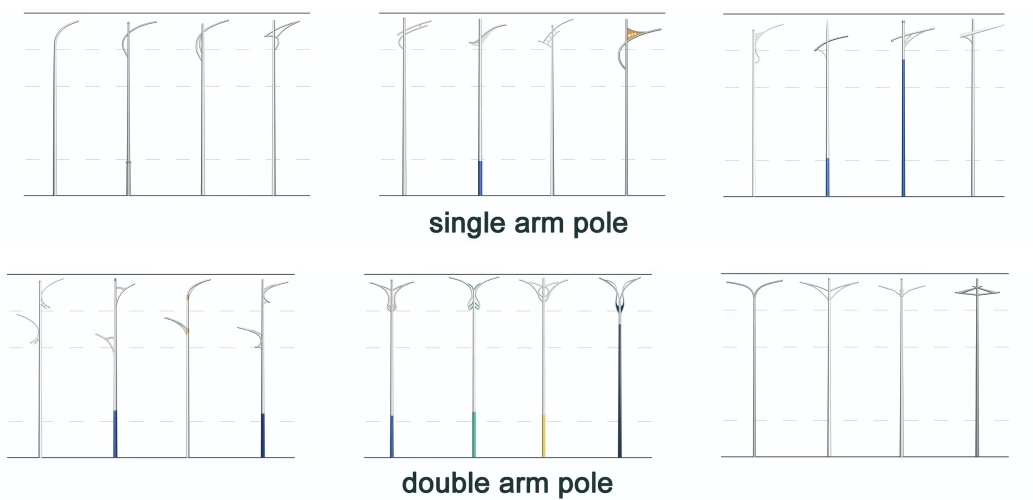

Shape Type |

Conical pole, Octagonal pole,Square pole, Diameter pole |

||||||

|

Arm Type |

Customized: single arm,double arms,triple arms,four arms |

||||||

|

Stiffener |

With big size to strength the pole to resist the wind |

||||||

|

Powder coating |

Thickness of powder coating is 60 -100um. Pure polyester plastic powder coating is stable and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). |

||||||

|

Wind Resistance |

According to local weather condition, General design strength of wind resistance is ≥150KM/H |

||||||

|

Welding Standard |

No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. |

||||||

|

Hot-Dip Galvanized |

Thickness of hot-galvanized is 60 -100um. Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. |

||||||

|

Anchor bolts |

Optional |

||||||

|

Material |

Aluminium,SS304 is available |

||||||

|

Passivation |

Available |

||||||

Product Description

Custom Street Light Pole with Single Arm is a high quality street lamp pole .

Made of high-quality Q235 steel and processed through precise welding techniques, the lamp post ensures overall strength and can withstand strong winds (wind resistance level up to level 12), vibrations and extreme weather.

Youdaoplaceholder0: The surface is treated with hot-dip galvanizing (average zinc layer ≥85μm) and powder coating, with excellent corrosion resistance, suitable for harsh environments such as coastal and high humidity, with a service life of more than 20 years.

Size customization : Pole height (6m-15m), arm length (1m-4m), tilt Angle can be adjusted according to requirements to fit different road widths and lighting coverage.

Exterior Design : Available in a variety of colors (Classic black, silver-gray, dark blue, etc.), surface textures and custom shapes that blend perfectly into the urban landscape or match the project theme.

Function Expansion : Reserved installation interfaces for cameras, surveillance equipment, billboards, solar panels, 5G base stations, etc. Supports multi-functional integration of smart city.

It is compatible with LED lamps, intelligent dimming systems and remote control systems. It can be combined with light sensors, time control or Internet of Things modules to achieve energy conservation and consumption reduction (with an energy-saving rate of up to 60%) and on-demand lighting.

The single-arm design ensures uniform light distribution, reduces glare, and enhances the safety of pedestrians and vehicles.

Modular structure design, supporting rapid assembly; The base is fixed with flange plates and is suitable for installation on concrete foundations or anchor bolts, reducing construction costs.

The inspection door is ergonomically designed, allowing maintenance personnel to easily conduct line checks or equipment replacements.

Design of Pole

Production Details

Packing Details

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory.

Q2: Where is your factory located? How can I visit there?

A2: Our factory is located in Yangzhou City, Jiangsu Province, China, about 2 hours drive from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: What's your MOQ?

A3: 1 set.

Q4: How does your factory do regarding quality control?

A4: 100% of the lamps will be tested and keep lighting for 24-72 hours to test its quality reliability, and we will also test its temperature after 24 hours' lighting.

Then after it is cool we again test 100% of the lamps to see if it still work well . Each lamp should pass all these QC procedures before shipping to customer.

Certification

Send your message to us:

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.